For sophisticated laboratory applications and for finished product or goods receipt inspection. Particularly useful where conventional moisture measuring methods, such as drying oven and Karl Fischer titrations are too time-consuming.

- Laboratory moisture instrument for rapid moisture analysis

- No grinding, weighing before and after the test, or use of chemical reagents.

- Not affected by varying product properties e.g. density, color or physical state

- The sample under analysis is neither modified nor heated and can usually be returned to ongoing use.

- Ideal when the process requires rapid and accurate results

- Up to 200 different items with the corresponding calibrations and measurement data can be saved in the device memory. A backup function is also available for saving stored data to a USB drive, transfer to PC or printer

- Results are stored in the instrument together with the date, time and other operational details.

- Requires a commercially available monitor and PC-keyboard.

Hand-held for portable measurement

for quick moisture measurement during goods receipt inspection, or in storage.

M007 Mobile MW 1100 and MW 1100S Series

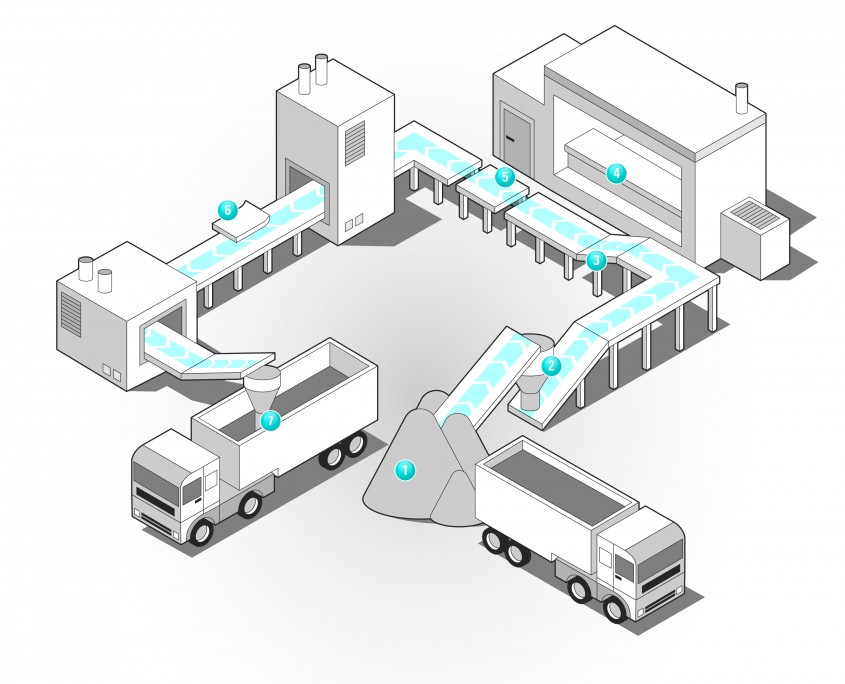

Sensor installation in the Silo hopper

Online measurement: Directly in the exhaust hopper or over a bypass.

M007, M007 Plus or M007 By-Pass

Sensor installation at ejection location

Sensor installation at the drop-off point at the end of a conveyor.

M007 or M007 Plus

Laboratory sensors for measurement on samples

For quality control and for ensuring quality, for product development or goods receipt inspection.

M007 Lab MW 1150, for routine measurements

M007 Lab MW 4300 or MW 4310 series for sophisticated laboratory applications.

Vibrating conveyor system

Installation of the planar sensor directly in a vibrating conveyor.

M007 Plus and special cable set.

Sensor installation in the sliding block

Installation of the M007 sensor above the product stream before the swaging, or granulating, of material on conveyor belts.

M007, M007 Plus or M007 By-Pass

Sensor installation in the wall on the buffer silo

Installation of the planar sensor between two conveyor belts, or vibrating conveyors.

M007, M007 Plus or M007 By-Pass

Hoppers, brushes, dishes

Spare beakers for beaker sensors

Analog remote display