Versatile standalone Inline system specifically designed for instant analysis of moisture and density of fast flowing material at a processing line.

The instrument has the capacity to measure, process and record over 3500 moisture reading per second

In real time, the moisture value of the product is instantly made available in a numerical form via a built in display. The speed and form of the numerical value displayed can be easily regulated.

Simultaneously or separately, the moisture and density values can be exported to other software or hardware clients and be used for further data processing or control purposes.

The instrument is designed in a way that performs without altering or damaging the material during analysis. Additionally, the physical qualities of the material does not affect the instrument’s performance.

Over 200 different calibrations and 4000 readings can be stored in the system memory with interface for transfer of values to PC or printer

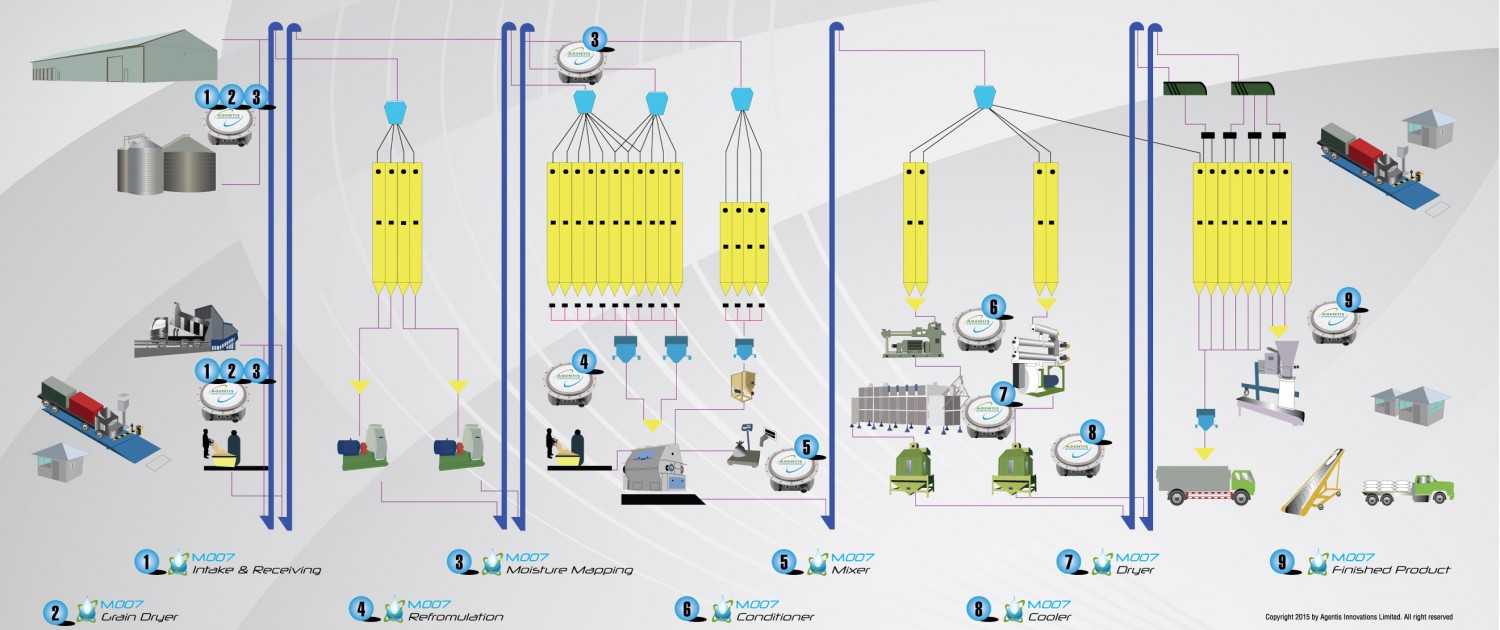

Compatible with every type of production plant, new or established and can be deployed at any point from the start of the process to finished product

Simple integration with mechanical and process control systems regardless of age of installations

Contains a complete set of standard interfaces for sensor value output, the transfer of control signals or for communication with control units.

One time commissioning and calibration and very low maintenance requirements

Standard number of Input/Output for control and alarm function

Wireless modem Mod35i for remote operation/service